- FLRN36-40.5D indoor AC high-voltage sulfur hexafluoride load circuit breakers, load switch-fuse combination appliances and cable-mounted load switches are designed and developed by our company by absorbing foreign advanced technologies and combining with my country’s operating requirements. The product has been fully type tested and its performance meets the requirements of GB3804 “3~63kV AC high-voltage load switch”

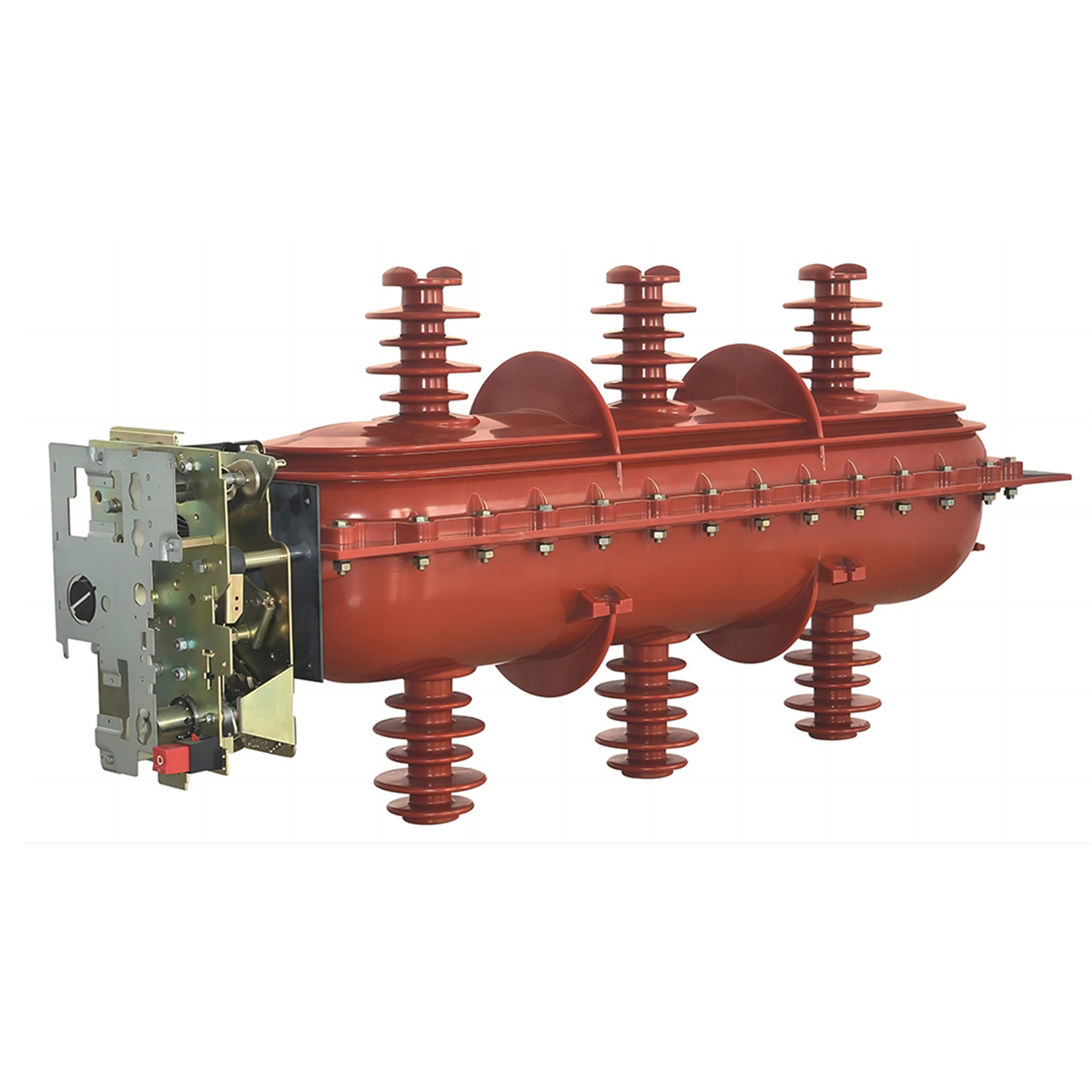

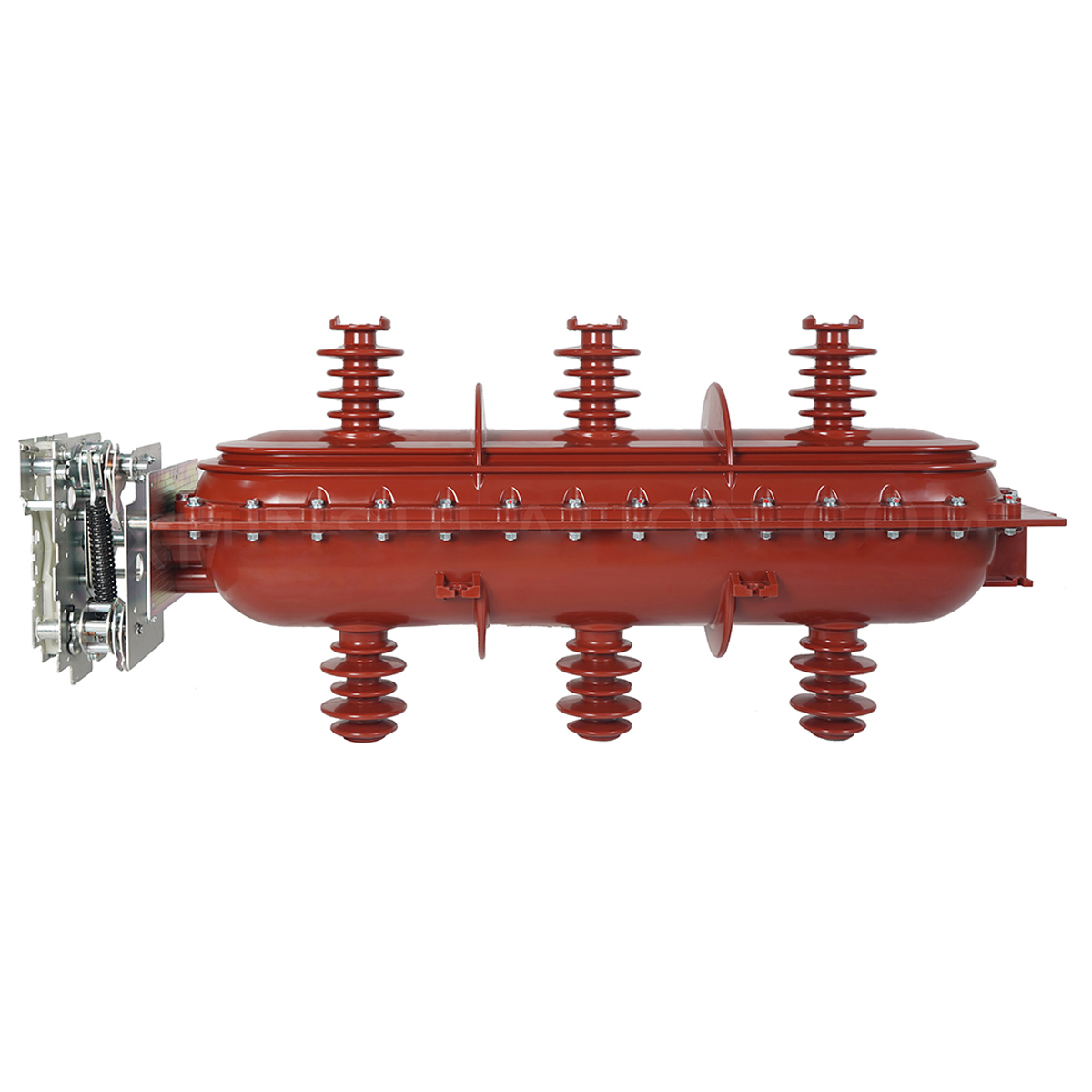

FLN36-40.5D SF6 load circuit breaker 36KV LBS spacing 350MM

Description

- FLRN36-40.5D indoor AC high-voltage sulfur hexafluoride load circuit breakers, load switch-fuse combination appliances and cable-mounted load switches are designed and developed by our company by absorbing foreign advanced technologies and combining with my country’s operating requirements. The product has been fully type tested and its performance meets the requirements of GB3804 “3~63kV AC high-voltage load switch”

- GB16926 “High-voltage load switch-fuse combination appliances”, IEC60265, IEC60420 standards. The product has a “close-open-ground” three-position arc extinguishing chamber, reliable interlocking, high insulation strength of the break, large creepage distance design, and the outlet is protected by a voltage-equalizing protection cover. The cable-mounted load switch has a touchable cable front connector at the outlet, and high-voltage cables are installed on the incoming and outgoing lines, and is used in the cable branch (connection) box. The switch has a special dynamic seal and fixed seal design, which ensures reliable sealing. A pressure gauge is installed in a prominent position for monitoring during operation to ensure safe operation. It is a new generation of high-voltage switchgear equipped for urban power grids.

- Operating environment

- Altitude: The maximum altitude of the equipment installation site is 1000m;

- Ambient air temperature: upper limit +40C, lower limit -15C;

- Ambient humidity: daily average relative humidity is not more than 95%, monthly average relative humidity is not more than 90%;

Earthquake: earthquake intensity does not exceed 8 degrees; - Ambient air should not be obviously polluted by corrosive and flammable gases, water vapor, etc., and there should be no frequent severe vibrations.

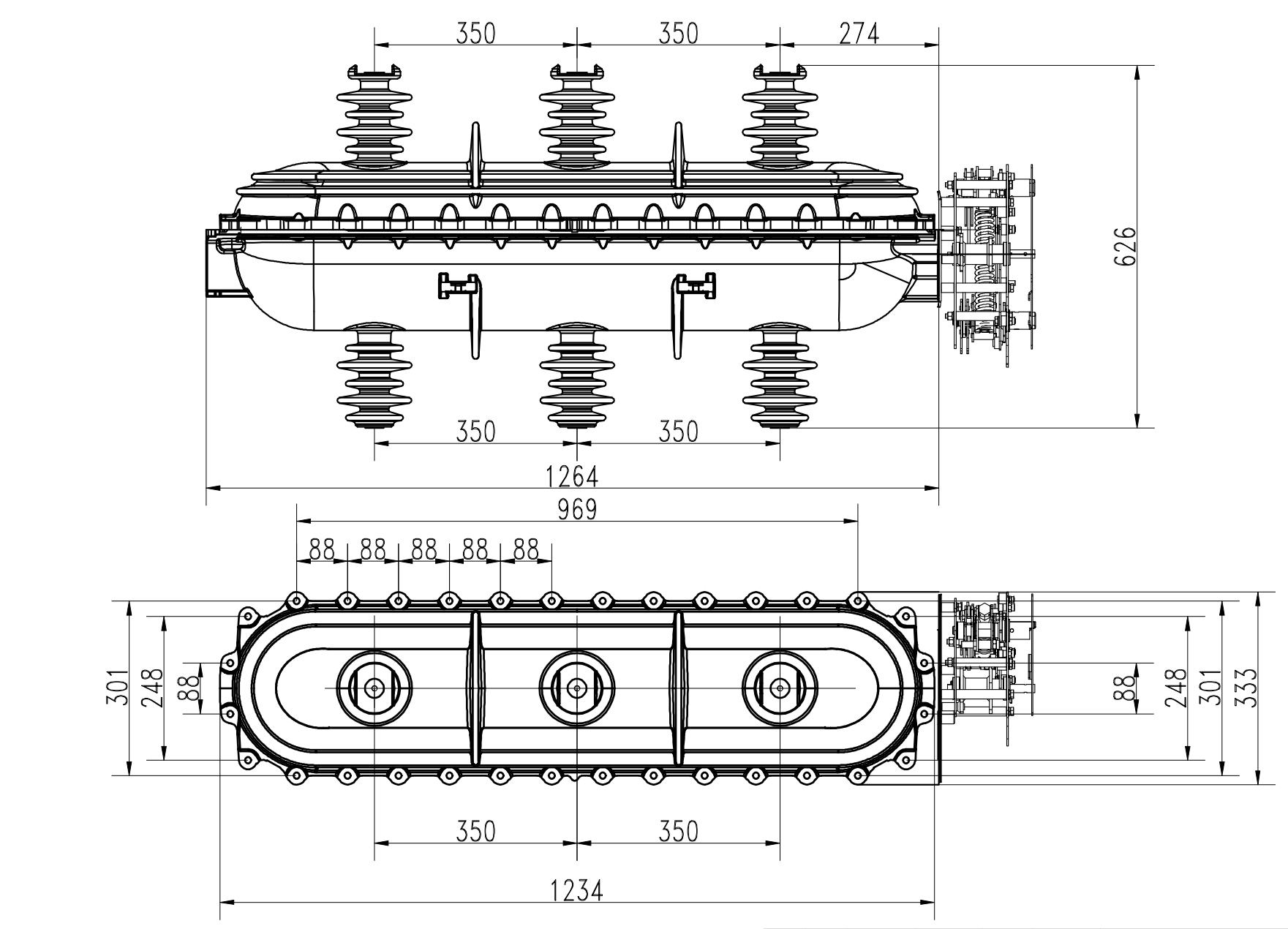

Product size:

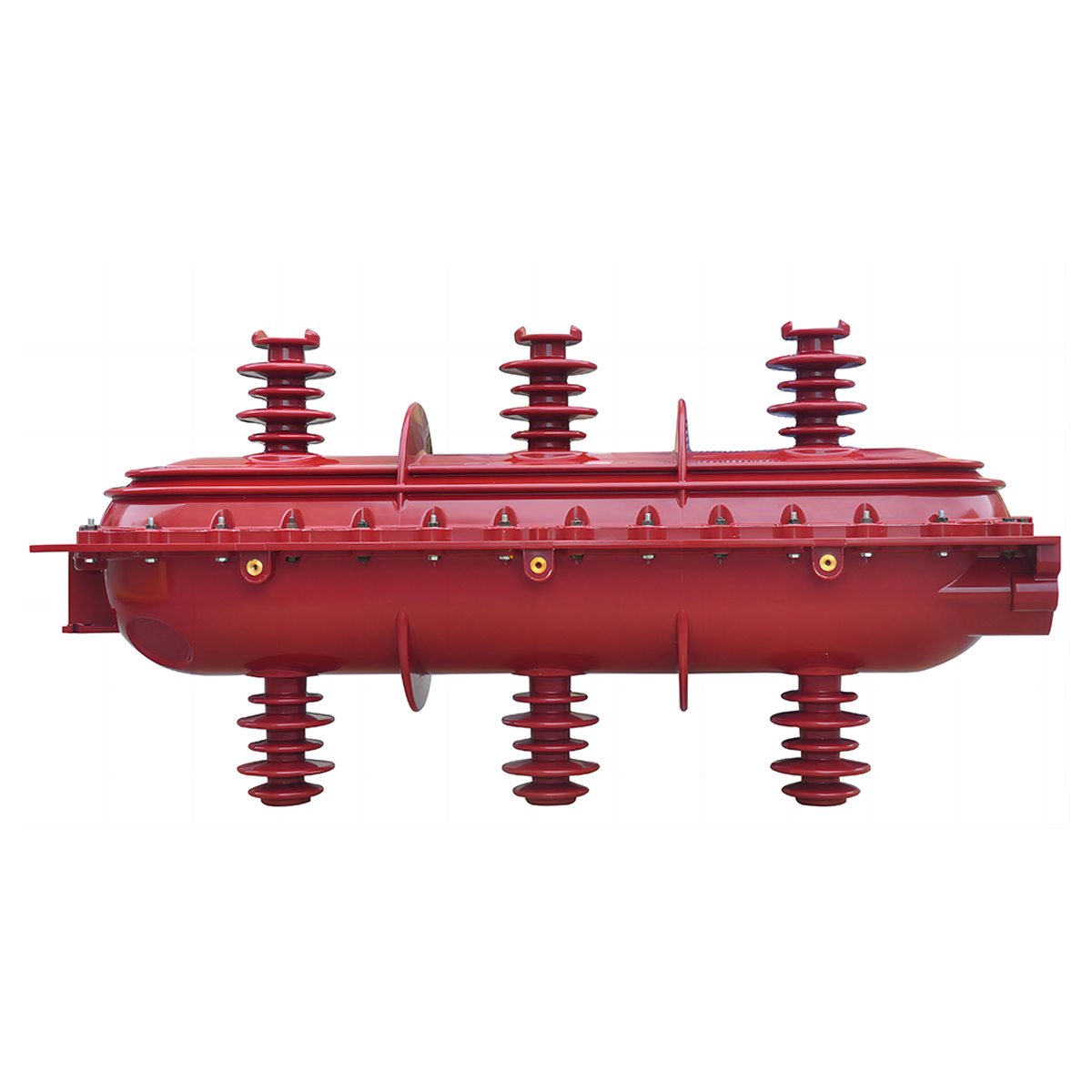

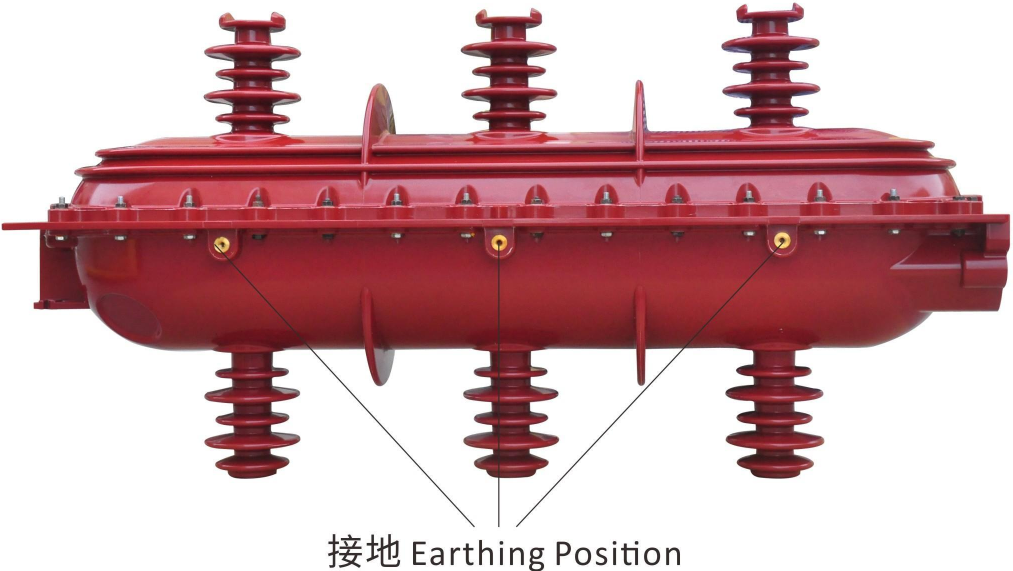

Structural Features:

- The load switch adopts double-break, rotary movable contacts and has the following three states: closing; opening; grounding.

- Good insulation performance. The load switch uses SF6 as arc extinguishing and insulating medium. The switch is sealed by an upper and lower shell cast by epoxy resin.

- Good safety performance. If arcing occurs internally, there is a structural weak point at the rear of the enclosure that will burst open, and then the arc vent valve on the cabinet will open and direct the overpressure airflow to the outside of the cabinet.

- It can be operated manually or electrically, and the operation is convenient and reliable.

- Three-phase integral installation, good periodicity, small number of parts, easy adjustment and installation, simple and easy, and long life.

- Each load switch is sealed and maintenance-free for life.

- The load switch and operating mechanism are placed in the detachable upper unit. It is easy to change the load switch cabinet into a load switch + fuse combination electrical cabinet, or change the load switch + fuse combination electrical cabinet into a load switch cabinet. .

- It can be used as a compact, miniaturized, frequent operation and other places.

Operating Mechanism

The spring operating mechanism of the load switch and its combined electrical appliances is divided into single spring operating mechanism and double spring operating mechanism. The FLN36-12D load switch equipped with a single spring operating mechanism is mainly used for the incoming and outgoing line control unit. The FLRN36-12D load switch-fuse combination appliance equipped with a double spring operating mechanism is mainly used for transformer protection units.

Usage Environment

- Ambient air temperature: upper limit +40℃, lower limit -15℃.

- Environmental humidity: The daily average relative humidity is not greater than 95%, and the monthly average relative humidity is not greater than 90%.

- Altitude: The maximum altitude of the equipment installation site is 2000m.

- Earthquake: The earthquake intensity does not exceed 8 degrees.

- There is no serious pollution in the surrounding air, such as dust, smoke, chemical corrosives, flammable gases, gasoline and salt agents, etc.

- If you have special requirements, please indicate them when ordering.

Installation

- The product is packaged in a single unit when it leaves the factory. Before unpacking, check whether it has been exposed to rain or moisture. The product should be unpacked indoors. After unpacking, you should conduct a visual inspection of the product to see if it is damaged or damp, and check whether the accompanying accessories and technical information are complete according to the packing list.

- After unpacking the product, dust, dirt, etc. on the product should be removed.

- Before the product is put into use, it should be confirmed whether the usage environment conditions are consistent with the specified requirements, otherwise measures should be taken.

Commissioning

The product has been strictly commissioned before leaving the factory. The installed product should be debugged as follows:

- The speed of just separating and closing should meet the requirements of the factory inspection sheet.

- Perform 10 closing and opening operations on the load switch and grounding switch. For those equipped with an electric mechanism, 5 closing and opening operations should be performed at the rated operating voltage each time. The action should be reliable.

- Use a simulated fuse to conduct an impactor opening test on the combined electrical appliance, twice for each phase. The action should be reliable, and the closing operation cannot be achieved after opening.

- Conduct a power frequency withstand voltage test on the product according to the parameters on the factory inspection sheet.

Usage

- The load switch in normal operation should be in the closing state, the grounding switch should be in the open position, and the grounding switch cannot be closed.

- During maintenance, the load switch should be opened first and the grounding switch can only be closed after confirming that there is no power at the cable end of the load switch.

- When replacing the fuse, make sure that the combined electrical appliance is automatically opened before closing the grounding switch and lower grounding knife.

- The fuse should be installed according to the instruction manual provided by the manufacturer. When installing, the striker of the fuse should be installed in the correct upward direction. Unless it is confirmed that a certain phase fuse does not pass the fault current, the three-phase fuse will be blown after the combination appliance automatically opens. Regardless of whether the firing pin pops out or not, all should be replaced.

- Load switch. When operating the combined electrical appliance, insert the handle rod into the operating hole and turn it 180 degrees clockwise to close. Otherwise, it is open. The opening of the combined electrical appliance can only be operated through the opening button.

- Users can install a padlock on the lock of the operating mechanism as needed to prevent misoperation.

Maintenance

Under normal use conditions where the environment meets the requirements of the installation and operation instructions, the switch body is guaranteed to be maintenance-free for 20 years. Due to environmental differences, necessary inspection and maintenance work on the load switch is still required.

- According to the working environment, conduct appropriate visual inspection of the insulation cover between June and December, and remove dirty and damp surfaces.

- Carry out lubrication and operation inspection of the operating mechanism 1 to 2 times a year to ensure normal operation. After the cumulative number of mechanical operations is 2,000 times, the performance of the mechanism should be checked.

- For load switches equipped with pressure gauges, the readings of the pressure gauges should be checked from time to time.

- When a fault current passes through the load switch fuse combination appliance and one phase fuse blows, all three phase fuses must be replaced. When replacing, the grounding switch must be closed first before replacement, and ensure that all three-phase fuses are installed in place.

- Users cannot arbitrarily replace electrical components that are inconsistent with the original model.

- Users should perform maintenance and repairs on products under the guidance of professional and technical personnel. If necessary, they can consult the manufacturer.

| No. | Item | Unit | Parameter |

|---|---|---|---|

| 1 | Rated voltage | KV | 40.5 |

| 2 | Rated frequency | Hz | 50 |

| 3 | Rated current | A | 630 |

| 4 | 1min Power frequency withstand voltage | wet | KV 95 |

| dry | 95 | ||

| 5 | Lightning impulse withstand voltage | KV | 185 |

| 6 | Rated short circuit breaking current(peak) | KA | 20 |

| 7 | Rated activeload and close circuit breaking current | A | 630 |

| 8 | Rated transferring current | A | 630 |

| 9 | Rated short circuit making current(peak) | KA | 63 |

| 10 | Rated cable(line)charging breaking current | A | 10 |

| 11 | Cable charage breaking current in earthing fault | A | 30 |

| 12 | Rated withstand current (peak) | KA | 63 |

| 13 | Short time withstand current(2s) | KA | 25 |

| 14 | Mechanism life | time | 5000 |