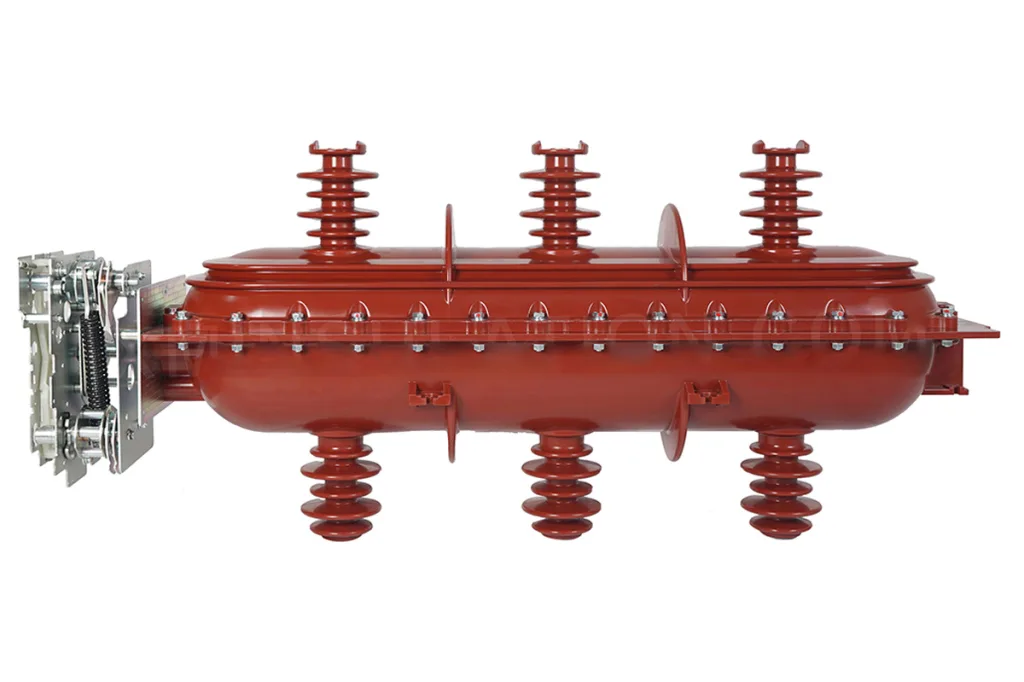

Impact of Epoxy Resin Composition on 36kV Load Switch Performance

3.1 Dielectric Strength and Electrical Insulation

Requirement: Must withstand 36kV continuous + 65kV pulse (IEC 62271-1).

Optimal Formulation:

High-purity epoxy resin (low ionic impurities) prevents partial discharge.

Cycloaliphatic epoxy resin with silica filler provides excellent tracking resistance (CTI ≥ 600V).

3.2 Mechanical Strength and Durability

Requirement: Must withstand mechanical stress during switching operations.

Optimal Formulation:

Bisphenol F epoxy resin with glass fiber reinforcement provides high flexural strength (>120MPa).

Anhydride curing minimizes shrinkage and cracking.

3.3 Thermal Stability

Requirement: Must operate at temperatures ≤105°C (IEC 60480) without performance degradation.

Optimal Formulation:

MTHPA hardener + alumina filler for high thermal conductivity.

Tg (glass transition temperature) > 130°C to prevent softening under load.

3.4 Environmental Resistance

Requirements: Must be resistant to moisture, UV rays, and chemicals.

Optimal Formulation:

Cycloaliphatic epoxy resin for outdoor UV protection.

Hydrophobic additives to prevent moisture absorption.

4. 36kV Epoxy Insulation Industry Standards

Standard Requirements Epoxy Resin Solution

IEC 62271-1 65kV Lightning Impulse Withstand Voltage High-Purity Resin + Silica Filler

IEC 60243-1 Dielectric Strength >20kV/mm Low-Voiding Curing Process

IEC 60112 Comparative Tracking Index (CTI) >600V Cycloaliphatic Epoxy Resin + Anti-Tracking Agent

UL 94 Flame Retardancy (V-0) Al(OH)₃ or Halogen-Free Additives

5. Case Study: Epoxy Resin in 36kV Load Switches

5.1 Common Failure Modes Caused by Improper Formulation

Partial Discharge (PD) Erosion → Caused by impurities or voids in the resin.

Cracking Under Thermal Cycling → Poor Filler Distribution or Incorrect Hardener.

Surface Tracking → Insufficient CTI Resistance.

5.2 Best Practice Formulation

For 36kV load switch disconnectors, the ideal epoxy system includes:

Base resin: Bisphenol F epoxy resin (low viscosity, void-free casting).

Hardener: MTHPA (high thermal stability).

Filler: 60% silica + 10% alumina (for mechanical and thermal performance).

Additive: Hydrophobic agent (to prevent moisture intrusion).

6. Future Trends in Epoxy Insulation

Nanocomposite epoxy resin: SiO₂/Al₂O₃ nanoparticles for higher dielectric strength.

Bio-based epoxy resin: A sustainable alternative with comparable performance.

3D-printed insulators: Customized geometries using high-performance resins.

7. Conclusion

The composition of the epoxy resin is critical to the performance, reliability, and safety of 36kV load switch disconnectors. Key Takeaways:

Dielectric strength depends on resin purity and filler type.

Mechanical durability requires optimal curing and reinforcement.

Cycloaliphatic epoxy resins and hydrophobic agents enhance thermal and environmental resistance.

For 36kV applications, manufacturers must select high-purity, thermally stable, mechanically strong epoxy formulations that meet IEC and UL standards while ensuring long-term reliability.